MT-10® Reduces Temperature in Hydraulic Units

This article was originally submitted to us by Michael Fertig.

Broadway at the Beach is one of the most popular tourist destinations in the entire Myrtle Beach area. They’ve used Muscle products in many applications. This particular application highlights the addition of Muscle Metal Treatment MT-10® to the hydraulic systems of “The Cliff Hanger”.

The Cliff Hanger

The Cliff Hanger promises a hang-gliding experience where passengers lie in a vehicle. After being safely strapped in, the ride begins to turn. Once it reaches full speed, it lifts into the air flying you at an angle, gliding through the air.

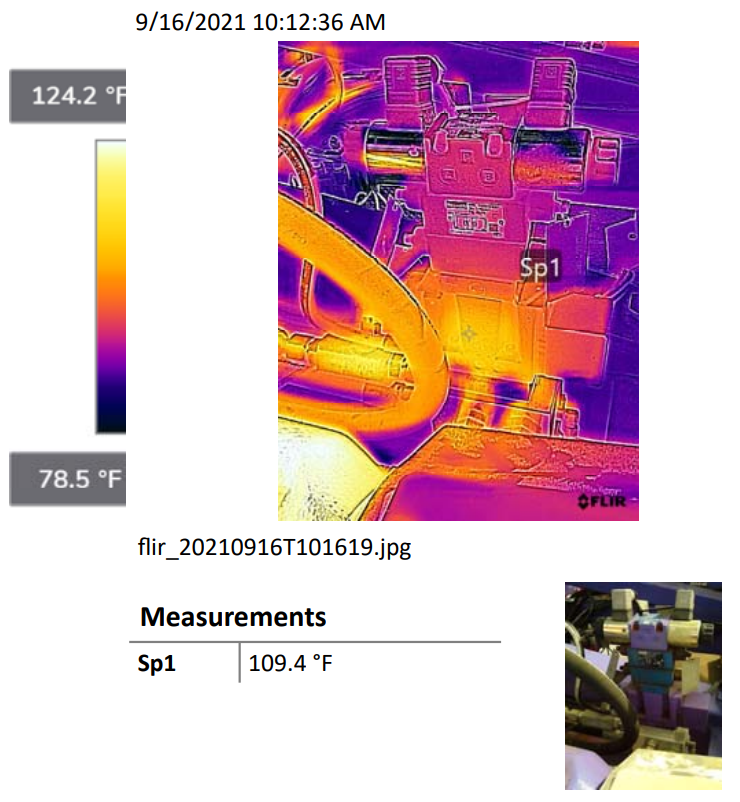

The temperature of these three hydraulic units is monitored by FLIR (Forward Looking Infrared). FLIR is a technology that detects thermal energy and creates infrared images of scenes without the need for scanning. It’s valuable for assessing equipment operating temperatures and detecting temperature variations by scanning hydraulic components, such as pumps, valves, and hoses. Hotspots or abnormal temperature patterns indicate potential issues like leaks, blockages, or excessive friction. The same camera model, FLIR ONE Pro LT, was used for all readings, which were taken about the same time of day. Due to the ambient heat, especially in the summer, it’s tough to keep these hydraulic systems cool.

The thermal images on the left were taken before Metal Treatment MT-10® was introduced to the system. MT-10® was then added to each unit in a 3% by volume ratio. The thermal images on the right were taken after the addition of MT-10® eight days later. A reduction in operating temperature can be seen in each unit after treatment.

Unit 1: Temperature Reduced 12.8 degrees (9.7%).

Unit 2: Temperature Reduced 7.3 degrees (6.3%).

Unit 3: Temperature Reduced 1.5 degrees (1.3%).

Click here to learn more about Metal Treatment MT-10® or Contact Us. Planning a trip to Myrtle Beach? Consider visiting Broadway at the Beach!